Understanding Maintenance and Repair for Swiss Lathe Machines

Swiss lathe machines are highly precise tools used in the production of small, intricate components. To maintain their performance and longevity, it is essential to implement regular maintenance and timely repairs. Proper care not only ensures consistent output quality but also reduces downtime and extends the machine’s operational life.

Importance of Regular Maintenance

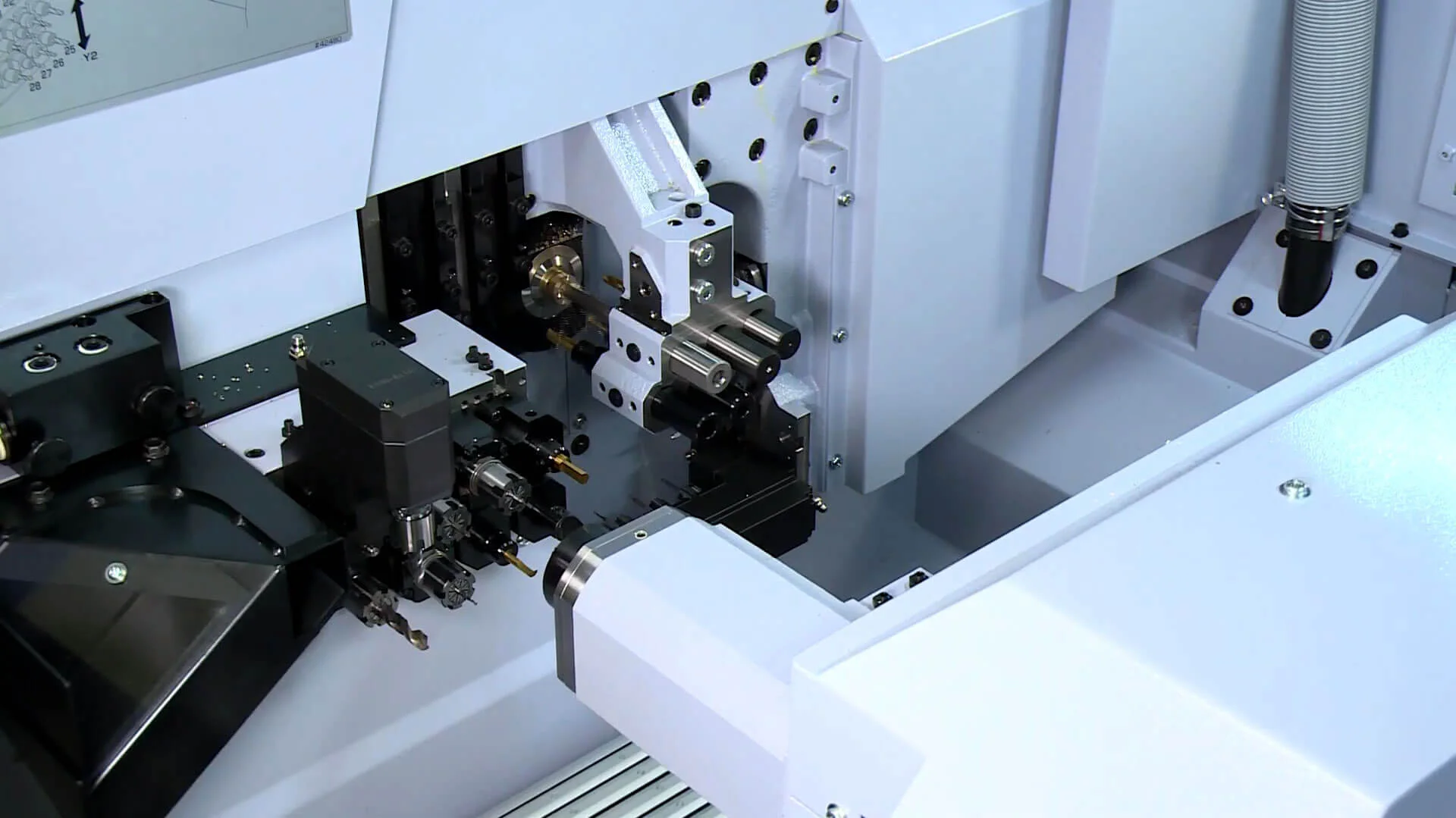

Routine maintenance is crucial for Swiss lathe machines because of their complex structure and tight tolerances. Key components such as the spindle, guide bushing, ball screws, and linear guides are subject to wear over time. Regular inspection, lubrication, and cleaning help prevent excessive wear, corrosion, and alignment issues. Scheduled maintenance also allows operators to identify potential problems before they escalate into costly repairs, ensuring that the machine operates at optimal efficiency.

Daily and Weekly Checks

Daily maintenance routines typically include checking lubrication levels, cleaning debris and chips, inspecting tool holders, and ensuring that moving parts are free of obstructions. Weekly checks may involve a more thorough inspection of belts, pulleys, and electrical connections. These preventive steps are critical for avoiding unexpected breakdowns and maintaining the accuracy of machined components.

Comprehensive Mechanical and CNC Maintenance

Swiss lathe machines combine mechanical precision with advanced CNC controls, and both aspects require attention. Mechanical maintenance includes monitoring spindle bearings, guide bushings, and feed mechanisms for wear or misalignment. CNC systems, on the other hand, require software updates, calibration checks, and inspection of wiring and control units. A reputable swiss lathe machine will have easily accessible documentation and maintenance guidelines that outline proper care procedures for both mechanical and electronic systems.

Lubrication and Coolant Management

Lubrication is vital for reducing friction and preventing premature wear of moving parts. Operators should use manufacturer-recommended lubricants and follow the prescribed schedules for application. Similarly, coolant systems must be monitored and maintained to ensure proper flow, temperature, and cleanliness. Clean and properly managed coolant helps maintain dimensional accuracy and surface finish while reducing tool wear.

Addressing Wear and Tear

Certain components, such as guide bushings, spindles, and tool holders, are prone to wear and may need periodic replacement. Monitoring these parts for signs of fatigue, deformation, or damage is essential. Timely replacement ensures that the machine continues to produce precise and consistent parts. Using genuine replacement components from reliable suppliers can prevent compatibility issues and further maintenance challenges.

Troubleshooting Common Issues

Despite preventive care, issues may occasionally arise, such as spindle vibration, feed inaccuracies, or CNC programming errors. Operators should be trained to identify symptoms, perform basic diagnostics, and address minor problems promptly. More complex repairs, including spindle replacement or advanced CNC calibration, should be handled by trained technicians to avoid further damage.

Importance of Documentation

Keeping detailed maintenance records is a valuable practice for managing Swiss lathe machines. Logs should include routine maintenance tasks, parts replaced, software updates, and any repairs performed. Accurate documentation allows operators and service personnel to track machine performance, plan preventive maintenance schedules, and make informed decisions regarding repair or upgrades.

Safety Considerations During Maintenance

Safety is a critical aspect of maintenance and repair. Operators should always follow recommended procedures, including shutting down the machine, securing moving parts, and wearing appropriate protective equipment. Proper training and adherence to safety guidelines prevent accidents and ensure that maintenance tasks are carried out efficiently.

Conclusion

Effective maintenance and repair practices are essential for keeping Swiss lathe machines operating at peak performance. Routine inspections, lubrication, coolant management, monitoring wear, troubleshooting, and maintaining accurate records all contribute to machine reliability and product quality. By implementing a structured maintenance program and addressing repairs promptly, manufacturers can extend the life of their Swiss lathe machines, minimize downtime, and ensure consistent precision in every production run.